As the global semiconductor shortage continues, manufacturers are dealing with the problem in a variety of ways. Their ingenuity, such as reusing semiconductors taken out of washing machines, reducing functions, and rewriting programs, is tear-jerking.

With a global semiconductor shortage nearly two years old, manufacturers are trying to keep production lines running in unconventional ways.

For example, automakers are using chips taken from washing machines and reprogramming them to reduce the number of chips. Or there are even cases where the car is shipped without the semiconductor on the premise that it will be installed at a later date. As semiconductor shortages become the new normal, everyone is being forced to take action.

“The market is desperately trying to respond,” says Bill Weisman, senior partner at McKinsey & Company. “Let’s say a manufacturer making a $350,000 mass spectrometer could not ship it because it didn’t have a 50-cent chip.

McKinsey has set up a dedicated team to procure semiconductors for its clients in response to the emergency. Wiseman explains that the team has expanded beyond the usual supply chain to find the coveted chips in countries like Morocco, the Netherlands and Japan.

They also found a product that was slightly different from the original request. Naturally, manufacturers and intermediaries can raise prices, and customers have no choice but to accept them. “Semiconductors do exist. The only question is how to find them and get them,” Weisman says.

Sometimes it seems like you have to work really hard to get it. In April 2022, Peter Wenning, CEO of Dutch semiconductor equipment giant ASML, revealed a surprising inside story. A large corporate group is said to be buying up washing machines just to take out and use semiconductors.

Table of Contents

ToggleThe Importance of Semiconductors Revealed

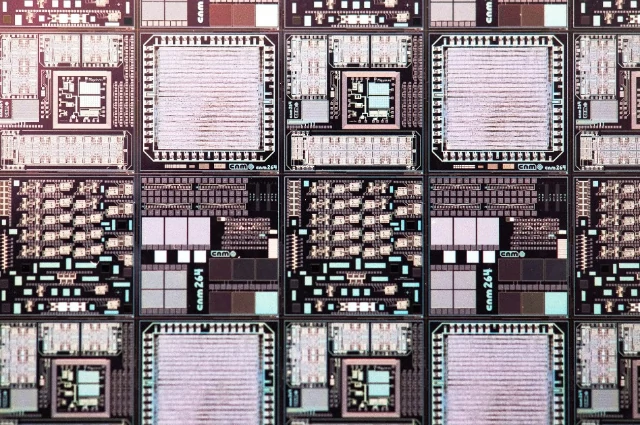

There are multiple factors behind the shortage of semiconductors. Demand for home appliances increased due to remote work due to the pandemic of the new coronavirus (global pandemic), and semiconductor hoarding occurred due to trade friction between the United States and China. And there was logistical chaos in the complex semiconductor supply chains scattered around the world.

The crisis highlights the importance of semiconductors to the economy and the number of fragile supply chains. In addition to home appliances, industries such as lighting such as LEDs, energy, and automobiles have been greatly affected.

At the beginning of the pandemic, automakers halted production and stopped ordering chips. However, it was later caught off guard by an increase in demand. Since then, automakers have struggled to keep up with the demand for semiconductors, which has fallen behind.

Instead of shutting down production lines, automakers began cutting features. In September 2021, Cadillac announced that it would give up installing semi-autonomous driving functions in some models. In November, Tesla began selling models without USB ports. And in May, Ford said it would ship some models without semiconductors for non-essential functions, such as heating control, and install them later at dealerships.

Mike Juran, CEO of Altia, which makes user interface (UI) automotive software, says many companies are rewriting their programs to make them work with different chips or make one chip do twice as much work. points out. In some cases, semiconductors from 10 years ago are used. “I substitute what I can get. I even bring out old things that are sleeping in the warehouse. It’s not the latest model, but you can use the same GUI.”

REad Also; Three Steps To Work Efficiently Even When You Can’t Use The Net

To the modern “toilet paper”?

The outbreak of the new coronavirus in China and Russia’s invasion of Ukraine have added to the disruption to supply chains. These new factors are also contributing to the prolonged semiconductor crisis.

Others, meanwhile, are finding new business opportunities in the crisis. For example, Smith & Associates, an electronic component broker, has added 300 new jobs to its existing 500 employees since the pandemic, according to Matt Hartzel, chief administrative officer. It is said that “Salaries are at an all-time high,” says Hartsell.

Hartsell says that while a few companies have stopped production, many manufacturers are doing whatever they can to keep production lines running. Chipplitics, a Sandia National Laboratories-licensed startup, has improved the efficiency of a method of quickly spotting counterfeits by sending signals to semiconductors. Distinguishing counterfeits is a very important issue for intermediaries and manufacturers who want to quickly procure semiconductors.

Dan Hutchison of TechInsights, which analyzes the semiconductor industry, says companies are doing whatever it takes to meet the chip shortage. Diversion from other products is one of them.

Hutchison warns that the current semiconductor shortage could quickly turn into a glut as demand for new products subsides as the economy cools. However, he said there may be another factor behind the current shortage. “There is a hoarding going on. Semiconductors may be modern toilet paper.”